How electric cars work?

Introduction

You will be surprised to learn that the first electric car appeared almost 130 years ago!

In the autumn of 1899, as part of the Berlin Motor Show, a race of self-propelled wagons with an electric motor was organized.

On a 38 km long section, an electric car designed by 22-year-old Austrian designer Ferdinand Porsche won in a race of 18 participants.

Such were the first electric cars – harbingers of modern electric vehicles.

Demand for electric vehicles is growing every year with an increase of 10-15%.

The inaccessibility of this type of transport for most people is explained not so much by a strong “oil lobby” or “collusion of auto giants”, but by an elementary misunderstanding of how this simple and convenient means of transportation works and functions.

In this article, we will take a detailed look at what a modern electric car is, how it works, its advantages and disadvantages, and whether it has a future.

What is an electric car?

An electric car is a car whose wheels are driven not by an internal combustion engine, but by electric motors powered by a battery pack or fuel cell.

Externally, the electric car is very similar to the usual with ice. However, there are a number of external signs that distinguish an electric car from traditional cars.

For example, the absence of a wide grille, a flat bottom, characteristic blue or green logos, and a very special whistling sound of the electric motor. But the main difference between an electric car and a car with an internal combustion engine is an electric motor.

![]()

In place of the internal combustion engine, a complex exhaust system, lubrication, cooling, transmission, fuel tank, and radiators there are compact electric motors and small radiators for cooling the battery located in the underground space.

In this regard, the number of rubbing parts has been reduced to a minimum, which means that a significant part of the funds and time for maintenance and repair has been saved. And there is nothing to say about the difference in cost between gasoline and electricity. As you can see, in fact, an electric car is a more efficient and at the same time simpler vehicle.

To know more you can come here.

The general principle of operation of the electric car

The principle of operation of an electric vehicle is the conversion of the chemical energy of the battery into electricity, which creates the torque of the rotor in the conductive winding of the electric motor, which in turn transmits it to the wheels.

The absence of a significant part of the mechanisms does not mean that the electric car can be assembled in any garage “on the knee”. Manufacturers invest heavily in the development of the most capacious batteries, reliable electric motors, and security systems. The main goal in creating an electric car is efficiency.

Did you know that so far the efficiency of a modern turbocharged internal combustion engine does not exceed 30%! The remaining 70% of the engine’s work goes to air heating, transmission losses, and harmful emissions.

At the same time, the efficiency of the power plant of even the most ordinary electric car is at least 85%. Moreover, each subsequent generation of batteries becomes more advanced – the capacity and ability to receive a larger amount of charge in fewer time increases.

Electric motors are able to develop a torque of 3-5 times greater at revolutions of 15,000-19,000 per minute, accelerate faster and brake more efficiently, using deceleration energy to charge the battery.

The internal design of the electric car

Most modern electric cars have a similar device. They differ in battery power, the number of electric motors, aerodynamics, and internal equipment.

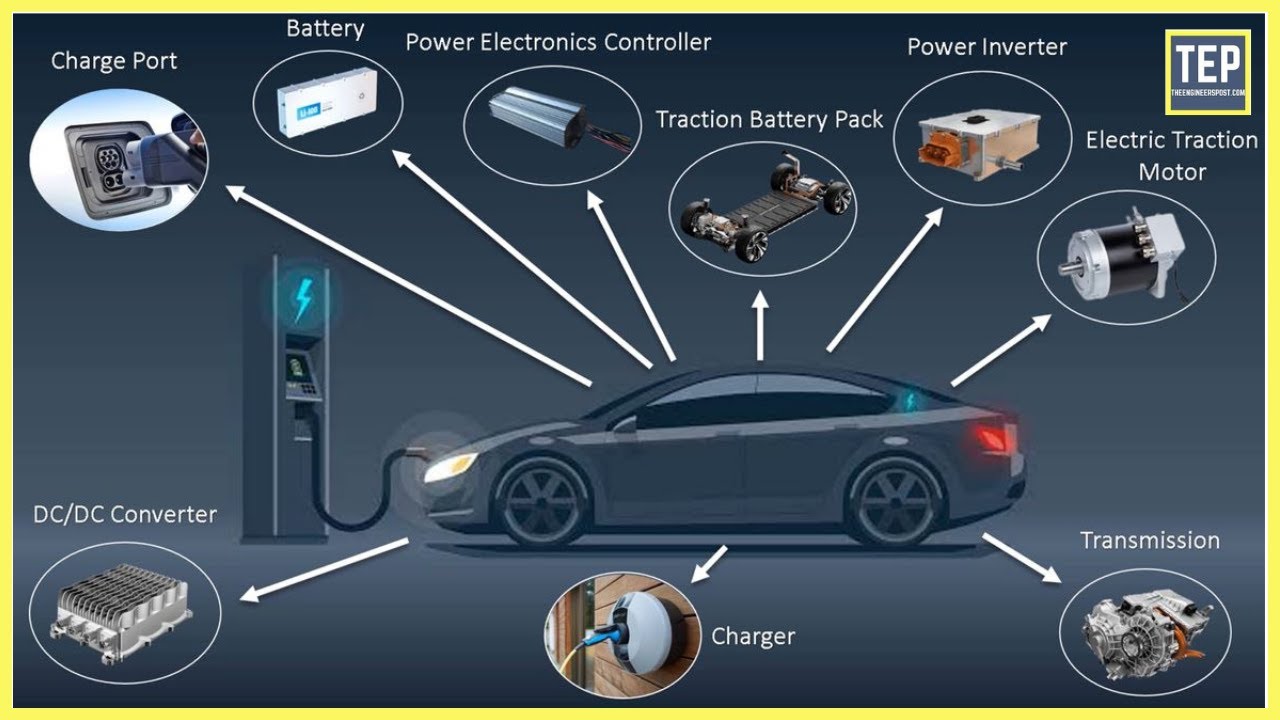

The main elements of the design of an electric vehicle are:

1. Rechargeable battery.

2. Electric motor.

3. Transmission.

4. Onboard charger.

5. Inverter.

6. DC converter.

7. Electronic control system.

8. Chassis.

The battery

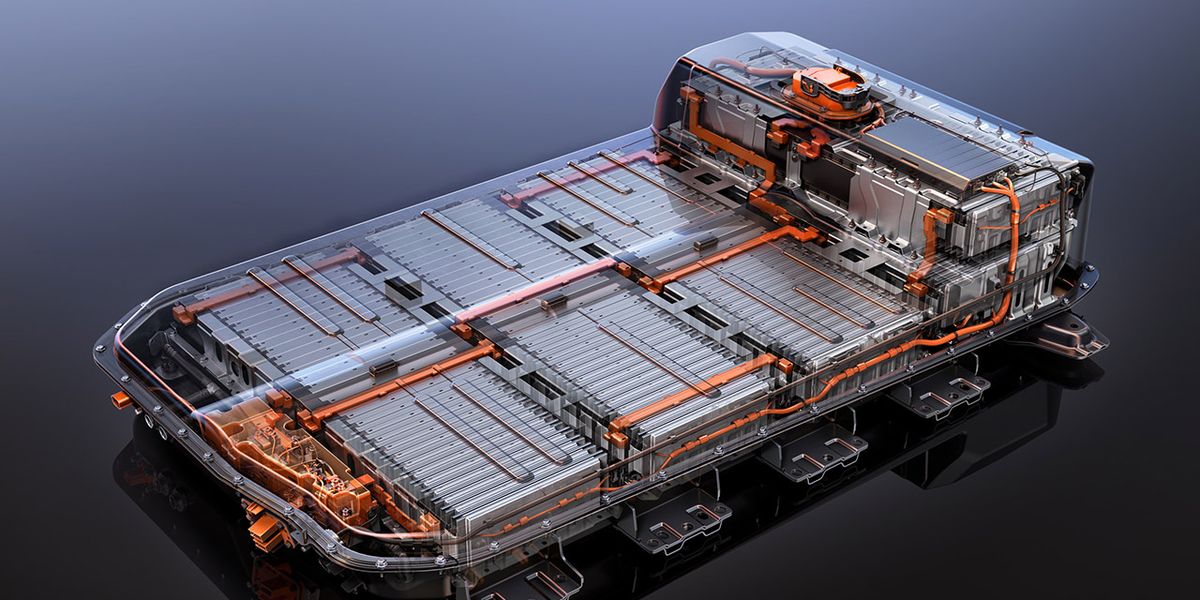

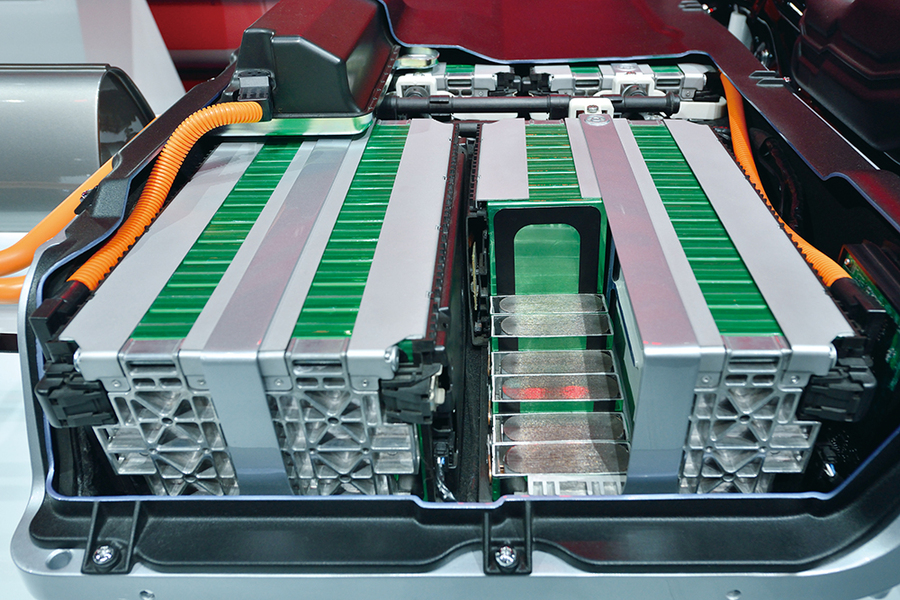

is the main component of an electric vehicle. It provides electricity to the traction motor and accessories of the vehicle. In modern electric cars, it is located in an underground space. The advantage of this placement is a low center of gravity and the release of useful space in the cabin and trunk.

The battery consists of cells, each of which contains several dozen ordinary household lithium-ion batteries of the AAA type. This solution allows faster cooling of rapidly heating elements.

The cooling system has multiple networks of channels filled with glycol refrigerant, the movement circuit of which is connected to compact radiators in the front air intakes. For this reason, most electric vehicles have a perfectly sleek streamlined profile.

The capacity of modern batteries, depending on the class of the electric vehicle, is from 40 to 100 kWh, which allows you to travel from 150 to 400 km on a single charge.

The charging port allows the electric vehicle to connect to an external power source to charge the traction battery. Today, there are about 5 types of charger ports. Manufacturers are trying to use the most popular type of port to greater market coverage.

DC-to-AC Converter

This device, called an inverter, converts the high-voltage DC power from the traction battery pack into the low-voltage AC power needed to operate the electric motors, and car accessories, and charge the auxiliary battery.

Read Also: Are tesla’s safe? 8 reasons why Tesla is the safest car

Electric motor

Using power from a traction battery, the engine drives the wheels of the car. Some vehicles use motor generators that perform the functions of drive and regeneration.

The classic electric motor consists of a conductive stator winding and a rotating rotor, which is driven by the magnetic field of the stator and transmits torque to the wheels.

There are two types of electric motors: synchronous, in which the magnetic field rotates simultaneously with the rotor, and asynchronous, in which the magnetic field rotates faster than the rotor.

The asynchronous motor changes the rotational speed depending on the AC frequency by simply pressing the accelerator pedal. This allows you to get if desired, the maximum torque for acceleration from a standstill.

Modern electric cars, depending on the power of the battery and engines, are able to accelerate from a standstill to 100 km / h in 5-7 seconds, which is comparable to the acceleration of a car with an engine capacity of 250-350 hp But the world’s fastest serial electric car Rimac C_Two is able to overcome the “hundred” in 1.85 seconds, faster than some 12-cylinder 6-liter supercars!

The undeniable advantage of electric cars is also the fact that the torque of rotation of the electric motor is linearly transmitted directly to the wheels. While the internal combustion engine converts the translational movements of the pistons into the rotation of the crankshaft and further through the system of gears and transmission frictions to the drive wheels.

To overcome such an “obstacle course”, the car needs more power, which means more fuel and engine size.

The onboard charger takes incoming AC electricity supplied through the charging port and converts it into DC power to charge the traction battery.

It also communicates with the charging equipment and monitors the characteristics of the battery, such as voltage, current, temperature, and state of charge, while the battery is charging.

Power Electronics Controller: This unit controls the flow of electricity supplied by the traction battery by adjusting the speed of the electric traction motor and the torque it generates.

The cooling system maintains the proper operating temperature range of the engine, electric motor, power electronics and other components. In the cold season, excess battery heat can be discharged into the cabin of an electric vehicle. For this reason, modern electric cars do not have a traditional stove.

Electric vehicle transmission

In the traditional sense, electric cars do not have a gearbox and a driven wheel drive, since the electric motor works efficiently in any speed range. Therefore, most electric vehicles have a single-speed box located next to the inverter.

This allows you to turn on the reverse mode, changing only the phases, as well as directing the braking energy into the battery charge.

A significant advantage of the electric motor and single-stage gearbox is that a “free” differential can be used. And in case of slippage of one of the drive wheels, instantly take away power in one of the semi-axles of the drive, reducing its slippage.

Chassis

The suspension system in electric cars is traditional and can often be borrowed from conventional cars. The main difference between the suspension of electric cars is that elastokinematics is forced to cope with a large weight, while the best weight distribution along the axes allows engineers to adjust the handling to cope with the inertia of the heavy body.

The braking system of an electric car is more cunning than usual. Traditional cars can effectively slow down when you press the brake pedal, and the braking energy is directed to heat the brake pads and discs.

In electric vehicles, the electric motor can be used as a generator to charge the battery. When the accelerator pedal is reset, the electronics recognize the slowdown in the rotation of the magnetic field relative to the rotor and slow down the car. In this case, the brake pedal can only be used to completely stop the electric car. Thanks to this, the service life of the brakes increases by an average of three times.

Conclusion

At the same time, the modern automotive industry shows us that almost all automakers have mastered the production of electric cars. Every year more capacious and powerful batteries are created.

Some manufacturers use components and assemblies of existing cars, and some, for example, VW Group or Tesla, are developing their own platforms exclusively for electric vehicles of the future.

Thanks to electric vehicles, modern technologies allow you to fully switch to autonomous driving mode. Already today, an electric car has become not just a means of transportation, but a mobile device in the broad sense of the word with access to the Internet.

He can update the software remotely, and drive to the service only for seasonal tire replacement.